Premium and Trusted Package Delivery Box Manufacturer and Supplier

As a professional manufacturer of mailboxes, package delivery boxes, and related products, we offer comprehensive solutions, from design and production to sales and service, ensuring global quality and satisfaction.

End-to-End Production Services

From raw materials to finished package delivery lockers, we provide end-to-end production services, covering design, manufacturing, testing, and delivery.

Custom Metal Fabrication

We provide custom metal fabrication services for package delivery boxes, capable of producing parcel drop box in various sizes and shapes to meet diverse application needs.

Fast Turnaround

Your pre-production samples can be ready in as little as 7 days, with bulk orders delivered in as fast as 30 days.

- Low MOQ

- 7-day Fast Proofing

- 50+ Designs

As online shopping becomes more convenient, small mailboxes can no longer handle the increasing number of packages. It’s time for an upgrade. PorchFlex offers an exclusive range of large package delivery boxes with custom options in various colors, sizes, and designs, perfect for both home and business use. OEM/ODM available.

Custom Freestanding Large Package Delivery Box

Package Drop Box with Letter Slot for Home

PF-PDB001

- Product Size: 1024*414*383mm

- Neight Weight: 18kg

- Material: Steel

- Package Size: 1077*484*145 mm

- Assembly Type: Ready-to-Assembly

Parcel Drop Box Front and Rear Access

PF-PDB004

- Product Size: 915*483*483mm

- Neight Weight: 21kg

- Material: Steel

- Package Size: 1005*573*573 mm

- Assembly Type: Fully Assembled

Lift Top Drop Box for Parcels

PF-PDB008

- Product Size: 850*410*430mm

- Neight Weight: 17kg

- Material: Steel

- Package Size: 940*480*500 mm

- Assembly Type: Fully Assembled

Modern Parcel Drop Pillar Box

PF-PDB007

- Product Size: 1000*350*270 mm

- Neight Weight: 15.5kg

- Material: Steel

- Package Size: 1090*450*370 mm

- Assembly Type: Fully Assembled

- Low MOQ

- 7-day Fast Proofing

- 50+ Designs

At PorchFlex, we offer custom metal mailboxes in a variety of styles. From the classic American design with its iconic flag, to the durable, large-capacity Australian mailboxes, and the elegant, ornate European styles. No matter your preference, we can customize each mailbox to fit your exact needs and taste.

Custom Steel Mailbox

American Mailbox

- No. PF008

- Product Size: 33.5‘’x16''x17''

- Net Weight: 37.5lbs

Australian Mailbox

- No. PF004

- Product Size: 36''x19''x19''

- Net Weight: 46lbs

European Mailbox

- No. PF001

- Product Size: 40.5‘'x16''x15''

- Net Weight: 39.5lbs

- Custom Fonts Available

- Versatile Materials

- Bulk Order Ready

Enhance property’s appeal with durable and stylish house numbers and signs. PorchFlex offers a wide range of customizable options in various fonts, finishes, and sizes to meet your business needs. Ideal for residential or commercial projects, our signs are built to last and easy to install. OEM/ODM available.

Custom Metal House Numbers & Signs

Lift Top Delivery Package Box

- No. PF008

- Product Size: 33.5‘’x16''x17''

- Net Weight: 37.5lbs

Front and Rear Retrieval Box

- No. PF004

- Product Size: 36''x19''x19''

- Net Weight: 46lbs

Front Retrieval Only Drop Box

- No. PF001

- Product Size: 40.5‘'x16''x15''

- Net Weight: 39.5lbs

Modern Parcel Pillar Box

- No. PF006

- Product Size: 39‘’x14''x15.5''

- Net Weight: 34lbs

Wide Custom Options for Your Unique Package Delivery Boxes

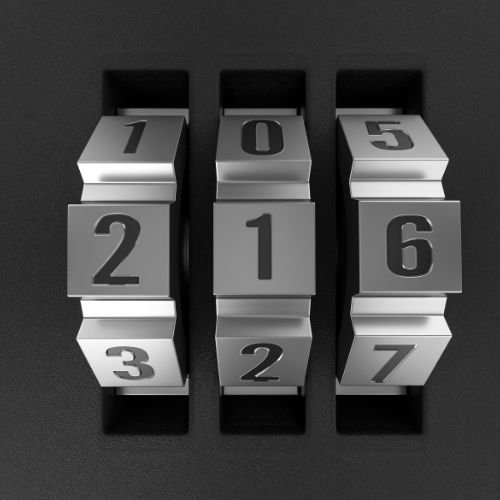

Custom Lock

We offer a variety of locking mechanisms to secure parcels inside package delivery boxes, tailored to your specific needs for security and convenience.

- Key Lock

- Combination Lock

- Dual Mode Lock

- key lock

- combination lock

- dual mode lock

Custom Material

Choose from a selection of durable materials to ensure your package delivery box is not only secure but also weather-resistant and long-lasting.

- Powder-coated steel

- Galvanized steel

- Stainless steel

- Aluminum alloy

- Brass

- Copper

Custom Finish

Enhance the appearance of your package delivery box with a range of finishes that provide both style and added protection against the elements.

- Powder Coating

- Brushed stainless steel

- Matte Finish

- High-gloss Finish

- Textured Finish

- Anti-graffiti Coating

Custom Slots

Tailor your package delivery box with a range of slot configurations to optimize the handling of your mail and packages, ensuring both efficiency and security.

- Large Slots

- Narrow Slots

- Circular Slots

- Rectangular Slots

- Custom-shaped Slots

Our 7-Step Package Delivery Boxes Manufacturing Process

1. Raw Material and Shearing Area: Cutting Metal Sheets to the Right Size

First, the raw metal coils are fed into an automatic shearing machine to cut them into the appropriate width and length. For our package delivery lockers, we commonly use sheet thicknesses of 0.6mm, 0.7mm, and 0.8mm. Typically, 0.8mm thickness is sufficient, offering a good balance between durability and cost. Some customers, especially those using fully assembled lockers, may opt for 1mm sheets.

However, for our large disassembled parcel delivery boxes, we usually suggest using 0.8mm sheets. This thickness makes manual bending and securing (especially for internal parts) easier. The disassembled design not only saves space during shipping but also reduces costs for both initial transport and final delivery. This allows sellers to stay competitive in a crowded market, and buyers can enjoy larger lockers at more affordable prices. Although some assembly is required, the process is straightforward, and we provide detailed instructions and video guides to assist with the setup.

2. Laser Cutting: Shaping Metal Sheets into Complex Forms

Using a laser cutting machine, we precisely cut metal sheets to achieve the various shapes and details required for our package delivery boxes. Laser cutting offers high flexibility, allowing us to easily adjust to different designs and specifications. This method not only reduces material waste but also enhances production efficiency, lowering manufacturing costs. As a result, your package delivery boxes are more cost-effective to produce.

3. Sheet Metal Punching: Precision Holes for Assembly

During the manufacturing process of our package delivery boxes, punching machines are used to precisely create holes in the bent metal sheets. These holes are essential for installing screws, hinges, locks, or ventilation features. Their precise location and size are crucial for ensuring the accurate alignment and tight connection of all parts during assembly.

We operate 6 punching machines, allowing us to handle multiple workpieces simultaneously, which significantly boosts production efficiency. Each machine is equipped with a variety of ready-made molds that can be quickly swapped out to meet different design requirements. Whether it’s for standardized production or customized orders, our punching machines offer the flexibility to accommodate diverse customer needs. By using punching machines, we reduce reliance on manual hole drilling, minimize waste, and take advantage of existing molds, thereby lowering mold production and replacement costs.

4. Sheet Metal Bending: Forming the Locker Components

In the manufacturing process of our home package delivery boxes and mailbox, a bending machine is used to precisely bend the sheared or cut metal sheets into the required angles and shapes. This process forms key components of the box, such as side panels, bottom panels, and door panels. By swapping out different molds, the bending machine can quickly adapt to various design requirements, ensuring that each bend is accurate and facilitates easy assembly in the next stages.

5. Spot Welding: Securely Joining Home Parcel Locker Components

Welding is a crucial step in securely connecting the various components of our package delivery lockers. We operate four manual spot welding stations and two spot welding machines to carry out precise and efficient spot welding operations. During the welding process, operators use the spot welding machines to quickly form weld points at designated locations, ensuring the strength and consistency of each weld. For tasks that require higher precision, our manual spot welding stations allow for fine control, ensuring that the weld quality meets the design specifications.

6. Powder Coating: Enhancing Durability and Appearance

In the powder coating process, the metal surface of the package delivery box is first cleaned and treated with a ceramic conversion coating to remove impurities and form a protective layer that enhances the adhesion of the powder. After cleaning, the surface is thoroughly rinsed and dried to ensure it is free of moisture. Next, electrostatic spraying equipment is used to evenly apply the powder to the metal surface. Finally, the package lockers are placed in an oven for high-temperature curing, which melts the powder and forms a strong, rust-resistant protective layer. This process not only increases the durability of the package boxes but also enhances their aesthetic appeal.

7. Custom Finishing Techniques: Adding Personalized Details

A. Silk Screen Printing Process

If a customer requests text or graphics on their package delivery locker, we typically use the silk screen printing process. After powder coating and curing, the parts that need text (such as the mailbox cover) are placed on the silk screen printing station. A technician positions a pre-prepared screen stencil over the metal surface. Using a squeegee, they evenly spread ink across the stencil, allowing the ink to pass through the open areas and transfer onto the metal, creating the desired design. Once printed, these parts are placed in a well-ventilated area to air dry naturally, ensuring that the design is clear and long-lasting.

B. Debossing Process

For customers who prefer a debossed design, a custom mold must be created, which incurs an additional cost. First, our designers craft the mold according to the customer’s specifications, ensuring precise and consistent debossing results. Once the mold is ready, the relevant parts of the locker are placed in a press machine, where the mold pattern is pressed into the metal surface, creating recessed text or graphics. This process is generally more costly than silk screening but delivers a more premium and durable finish.

8. Packaging: Disassembled and Fully Assembled Package Delivery Boxes

A. Packaging Process for Disassembled Package Delivery Boxes

After finishing processes, disassembled package delivery boxes are inspected. Components like the body, door panels, screws, and locks are protected with bubble wrap or foam padding. Parts are packed in a logical order in corrugated boxes to prevent damage, with accessory bags and installation instructions placed visibly. The sealed boxes are labeled and stacked on pallets for shipment.

B. Packaging Process for Fully Assembled Package Delivery Boxes

Fully assembled lockers undergo a quality check and are protected with bubble wrap, foam, or corner protectors. They are packed in reinforced cartons or crates with cushioning to prevent movement. Labels with product details are applied, and the sealed boxes are stacked on pallets for shipment.

Why Choose PorchFlex ?

Lighting Speed

- 8 hours x 5 days dedicated customer support.

- 7-10 days turnaround for sample orders.

- 3 weeks delivery for mass production runs.

Top Product Quality

- Rigorous 5-stage in-house quality checks.

- 1-year comprehensive after-sales support.

- Less than 1% defect rate, guaranteed.

Lower Your Risk

- Pre-production samples for peace of mind.

- Third-party inspections to uphold standards.

- Confidentiality to secure your designs.

Experienced Team

Tailored Customization

Globally Trusted Partner

Our China Package Delivery Box Factory

Our factory is packed with top-notch machines that make sure every package delivery box is built right. Take a look at the gear that helps us get the job done efficiently.

6-Step Custom Process For Home Package Delivery Boxes

These six steps ensure a smooth journey from concept to completion, delivering high-quality home package delivery boxes to your specifications.

STEP 1

Consultation and Quotation

We begin by understanding your specific needs and providing a detailed quotation based on your requirements.

STEP 2

Design and Sample Confirmation

Our design team creates a prototype based on your specifications, which we then refine and finalize with your approval.

STEP 3

Order Placement and Production Scheduling

After confirming the design, we place the order and schedule production, ensuring a seamless transition from planning to manufacturing.

STEP 4

Mass Production

We commence with mass production, adhering strictly to the agreed-upon specifications and timelines.

STEP 5

Quality Inspection

Each product undergoes rigorous quality checks at various stages of production to ensure it meets our high standards.

STEP 6

Packaging and Shipping

Finally, we carefully package the lockers and arrange for prompt shipment to your desired location.

What our customers say about PorchFlex?

Sophie Müller

Working with PorchFlex has streamlined our procurement process for package delivery boxes. Their ability to provide fully customized solutions that meet our specific requirements has been outstanding. The consistent quality and reliability of their products have made them our go-to supplier. Our clients are highly satisfied with the secure and durable boxes provided by PorchFlex

Robert Johnso

PorchFlex has been a reliable partner in our supply chain. Their package delivery boxes meet our high standards for durability and security, which are crucial for our distribution network. The flexibility in their production capabilities allows us to place orders in various sizes and specifications, ensuring we always have the right products for our clients.

Olivia Rossi

Partnering with PorchFlex has significantly improved our procurement operations. Their package delivery boxes are not only of exceptional quality but are also delivered on time, every time. The ease of communication and their understanding of our business needs have made them a trusted supplier. Our retail partners have expressed satisfaction with the consistency and performance of the products.

John Miller

PorchFlex has been an exceptional supplier for our growing needs. The quality of their package delivery boxes is unmatched, and their ability to scale production quickly has been crucial for us. The transparency in their processes and their commitment to sustainability are major reasons we continue to partner with them.

Julia Andersen

Choosing PorchFlex has simplified our procurement challenges. Their attention to detail and understanding of European standards ensured a smooth integration of their products into our operations. The ongoing support and quick response times have made them a valuable part of our supply chain.

Carlos Diaz

PorchFlex’s innovative designs and reliable delivery times have set them apart in the industry. We’ve seen significant improvements in customer satisfaction since integrating their package delivery boxes into our services. Their ability to deliver on promises has strengthened our business relationship considerably.

PorchFlex Knowledge

Package Theft Prevention Guide

What You'll Learn?

In this guide, you’ll discover how to prevent package theft, who’s responsible when it happens, and steps to take if your package is stolen. You’ll also learn effective prevention tips for both homes and apartments.

Lockable Package Delivery Box Guide

What You'll Learn?

This guide covers everything you need to know about lockable package delivery boxes. You’ll learn how they work, why they are essential, and how to choose the best one for your home. By the end, you’ll be equipped with practical insights to keep your packages safe.

- What Is A Package Delivery Box?

- How Do Package Drop Boxes Work?

- Why Package Delivery Boxes Become So Popular?

- What are the Advantages of Package Delivery Boxes?

- What Is the Best Package Delivery Box?

- How to Choose A Package Delivery Box?

- Where Do People Place Their Package Delivery Box?

- Why We Said Package Delivery Box Is the Game Changer?

- Best Selling Package Delivery Box on Amazon 2024

Manufacturing Process Guide

What You'll Learn?

In this guide, you’ll explore the essential steps involved in sheet metal fabrication. From shearing and laser cutting to welding and finishing, we cover all the processes to give you a complete understanding of metal fabrication techniques and materials.

- The Complete Guide to Sheet Metal Shearing

- The Ultimate Guide for Sheet Metal Laser Cutting

- The Ultimate Guide to Sheet Metal Bending

- The Ultimate Guide to Sheet Metal Stamping Parts

- The Complete Guide to Sheet Metal Welding

- Stainless Steel Fabrication - The Ultimate Guide

- Stainless Steel Finish - The Comprehensive Guide

- Galvanized Sheet Metal Fabrication - The Complete Guide